In 2019 RPE "TIK" announces the development of the first wireless vibration sensor with digital output (LoRaWAN standard) - TIK-WSV.

The sensor is designed to measure the RMS value of vibration velocity and vibration acceleration along two axes and transmit the signal to the base station wirelessly.

The start of sales of the wireless sensor is planned for the III quarter of 2020, the estimated price of the sensor is 50.000 RUB. Prior to the end of the II quarter of 2020, preliminary applications are accepted, a discount on the purchase of a sensor by prior order is 30%.

During 2019, as part of collective trips with the participation of the Perm Krai Export Support Center, RPE "TIK" took part in several foreign exhibitions that took place in Hannover (Germany) and Baku (Azerbaijan).

"Hannover Messe", or Hannover Fair - one of the largest exhibitions of high technology, innovation and industrial automation in the world. From year to year, unique opportunities are provided for establishing international contacts, establishing cooperation, attracting investments and expanding sales markets.

In its turn, "Caspian Oil & Gas" exhibition has been a great platform for a meeting of leading oil, gas and energy professionals in the Caspian region for a quarter of a century, where numerous memoranda, agreements and contracts are signed.

As part of these events, RPE "TIK" got the opportunity to get acquainted with the latest achievements of industry science and technology, as well as present their products and find new business partners.

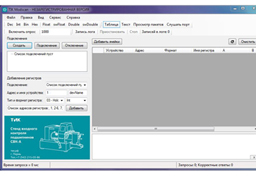

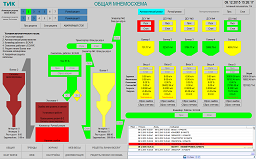

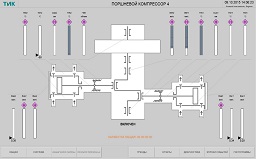

In 2019, TIK Modscan software was included in the Unified Register of Russian Programs for Electronic Computers and Databases, which means its full Russian origin (development) and allows use not only by individuals and companies, but also by government agencies.

Recall that TIK Modscan software is designed to develop, configure, maintain and operate equipment that supports the Modbus protocol. The program has a large number of functions (some of which are available only in the registered version, which can be purchased on the site by leaving a request), and also has a convenient and intuitive graphical interface.

At the beginning of 2019, the English version of the site of RPE "TIK" was launched. It provides an opportunity to get acquainted with the products of the enterprise not only to Russian customers, but also to foreign ones, as In recent years, the number of website visitors from abroad has grown significantly.

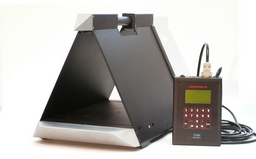

Production of the modernized portable vibration meters "PION-2" began.

Production of the modernized portable vibration meters "PION-2" began.

Since 1967, non-standard technical means for storage and retrieval of information have been developed. They were divided into two groups:

Since 1967, non-standard technical means for storage and retrieval of information have been developed. They were divided into two groups:

The history of "TIK" is closely connected with the Perm "Scientific and Research Institute of Control Computers and Systems" (SSRICCS).

The history of "TIK" is closely connected with the Perm "Scientific and Research Institute of Control Computers and Systems" (SSRICCS).

New product!

New product!